There is a great deal that needs to be taken into consideration through the entire purchasing process. As we continue to explore the complex, yet easily understood, supply chain management process, it is essential that, as with any process, control measures are in place to monitor the performance of the process.

One key performance indicator is monitoring the cultural alignment between the purchasing organization and vendors we work with. Often times this overlooked indicator can mean the difference between a good vendor partner, and the alternative. There are a number of things that could happen through either organization's life cycle that could cause a cultural conflict.

Before we explore what might cause a cultural, conflict let's first discuss the importance of cultural alignment. Much like our own interpersonal relationships, we need to maintain a healthy relationship with our vendors, suppliers, and contractors -- a relationship built on trust, and clear bilateral communications. In the buyer/vendor relationship, there must be a professional level of trust that can only be created when both parties actively listen, and actively communicate.

Often, when there is a change in leadership in either organization, the tone and culture of the applicable organization changes; thus, it is incredibly important that the supply chain management organization remain vigilant to changes within their most commonly utilized sources of products and services. One way to do this is through regular vendor audits, which we will discuss in greater detail later in this article.

As previously discussed one element of essential organizational importance is the independence of the supply chain management organization. This independence serves as a gatekeeper to ensure the purchasing process is always completed with the best interests of the organization in mind -- without any unnecessary personal biases or preferences. The best way to accomplish this independence is for the supply chain management group to report to an offsite entity. An example might be a production facility in Oregon having their supply chain management group report to the controller at a corporate office, or the corporate audit staff. In smaller organizations this might be difficult; however the independence can still be instilled through clear and concise leadership within the smaller organization.

One of the most difficult challenges the supply chain management team faces is managing the vendor relationship when there is an issue. Often times the buyers are stuck in the middle -- between the end user customer and the supplier, vendor, or contractor. As previously discussed good communication is key to solving these types of issues. Arranging a meeting between the vendor and the end user customer will often result in a much better understanding of the problem, and the two will work together to solve the problem.

Case Study 3:

Building on the previous two case studies, let's assume that after Jim specified his needs, the buyer, instead, successfully sourced and purchased a pump meeting Jim's specifications from a new but well-intentioned vendor that met all of the organization's new vendor requirements. Upon delivery the pump did, in fact, meet all of the specifications Jim outlined; however, after putting the pump into service, the pump failed due to an apparent bearing failure.

Case Debrief:

Jim was obviously displeased with the performance of the vendor's pump; however the buyer arranged a meeting with the vendor and Jim. During this meeting, it was determined that Jim did not clearly specify the service environment. Had the vendor known that the service environment was extremely harsh, then a mechanical seal with a different material would have been used. Jim, the buyer, and the vendor all learned from this experience and a product specification standard was created to insure this issue would never again occur.

This exemplifies the best manner in which to address vendor quality issues, while at the same time shows the use of a continuous improvement philosophy within the supply chain management and vendor relationship.

Another very important consideration is the establishment of ongoing evaluations to maintain a healthy relationship between the organization and the vendor, contractor, or supplier. Specifically, on at least an annual basis, every vendor should be evaluated to determine their continued ability to serve the organization well. This evaluation may include a cursory review, or a more in-depth review, which might include site visits and inspections of the vendor's facility.

When specifying capital purchases, there are a number of considerations that are entirely different than those applicable for consumable, or service, purchases. Capital purchases have long-term implications for the organization that the supply chain management function, as well as the requisitioning function, must be keenly aware of.

Through this section, we will step through the purchasing process in a capital purchase scenario. First, in the specification phase, there are considerations such as the total cost of ownership, or Life Cycle Cost. While this is similarly considered with non-capital purchases, these costs are significantly higher in a capital purchase environment. Second, we must consider the balance sheet and income statement implications of a capital purchase.

Case Study 4:

Acme Enterprises is a small, but growing, family-owned commercial cleaning organization. While Acme has been very successful to this point, they have outgrown their rented space, and have decided to build their new operations center. First though, they must complete the due diligence required to ensure the long-term viability of the purchase of land, and taking on the cost of owning a building.

First, Acme will specify their purchase. This is typically done in a request for proposal, or RFP, format. In the RFP, Acme will, in the most minute detail, spell out what they require, including the architectural drawings and associated engineering work necessary to allow a general contractor to bid the job. As you can see, this is quite different from the simple specification of a piece, part, product, or service.

Acme's current simplified income statement is outlined below:

|

Sales |

$1,000,000 |

|

Operating Costs |

$650,000 |

|

Net Margin |

$350,000 |

Acme's current simplified balance sheet is outlined below:

|

Vehicles |

$230,000 |

|

Inventory |

$45,000 Interested in learning more? Why not take an online Purchasing and Vendor Management course?

|

|

Cash |

$350,000 |

|

Total Assets |

$625,000 |

Keep in mind that the operating costs in the simplified income statement include the cost of depreciation for any physical assets, such as vehicles.

Taking into consideration the acquisition of land, engineering and architectural costs, permits, and construction, the following income statement and balance sheet projections would apply:

Acme's projected simplified income statement:

|

Sales |

$1,150,000 |

|

Operating Costs |

$850,000 |

|

Net Margin |

$300,000 |

Acme's projected simplified balance sheet:

|

Vehicles |

$230,000 |

|

Inventory |

$45,000 |

|

Cash |

$300,000 |

|

Building |

$300,000 |

|

Total Assets |

$875,000 |

In order for Acme to approve this project, they must first obtain financing. As you can see in the projections, Acme's operating costs have increased as a result of the potential of owning a building. These projected increases include the cost of financing, maintenance requirements for the building, and depreciation. Assuming a service life of the building of 30 years, Acme will incur an increase of $10,000 per year in operating expenses, just in depreciation costs (30 years x $10,000=$300,000).

Case Study Debrief:

As you can see, there are a number of additional considerations that must be thought through when making a capital asset purchase. There are long-term implications to the balance sheet and income statement, and the organization as a whole -- including the supply chain management function, which must be aware of the long-term effects of capital asset purchases on the organization.

In this case, Acme is able to support the additional debt and expense burden, because they have a 30 percent profit margin projected.

The second step in the capital purchase process is sending the RFP (Request for Proposal) out for bid. Generally this should be done in a sealed bid format to maintain the integrity of the process. With large capital projects, it is essential that the organization spell out every detail in the RFP in order to receive accurate bids, and to mitigate capital project scope creep. Scope creep occurs when an RFP is not as complete as it should be and changes are made by the buyer's organization during the capital project that require the contractor, vendor, or supplier to incur additional costs, and thus pass those costs on to the buyer's organization.

Another form of vendor, contractor, or supplier selection in capital purchase scenarios is through the utilization of state and federal contracted organizations. Your supply chain management team will best be able to determine if you are eligible to source via state or federal contract suppliers. These are often reserved for state or federal agencies, and organizations that are at least partially funded by state or local agencies.

As previously mentioned it is more important than ever that terms and conditions are thoroughly reviewed in a capital purchase scenario. Often times supply chain management, working with the legal team, will implement performance toll gates for capital projects, and require contractors, suppliers, and vendors to have some form of a surety bond that protects the buyer's organization should a contractor, vendor, or supplier fail to achieve a project toll gate. Terms and conditions in a capital purchase scenario may also include provisions for remedy should one party not fulfill their obligations under the scope of work attached to the terms and conditions. These remedies may include, refunds, discounts, cancellation without penalty, mediation, or legal recourse.

This process involves specifying, requisitioning, sourcing, and buying. In some cases, organizations attempt to streamline this process through implementation of alternate purchasing methods.

One such alternate purchasing method is a "blanket purchase order." In some cases, supply chain management may elect to issue a "blanket purchase order" to a preferred vendor to facilitate streamlined product or service delivery. This method offers the organization flexibility, allowing line supervisors to order what they need on the weekend, or during off hours; however, it is essential to ensure this type of purchasing system is closely monitored for potential abuse. Blanket purchase orders typically offer easy access to preferred vendors, products, or services.

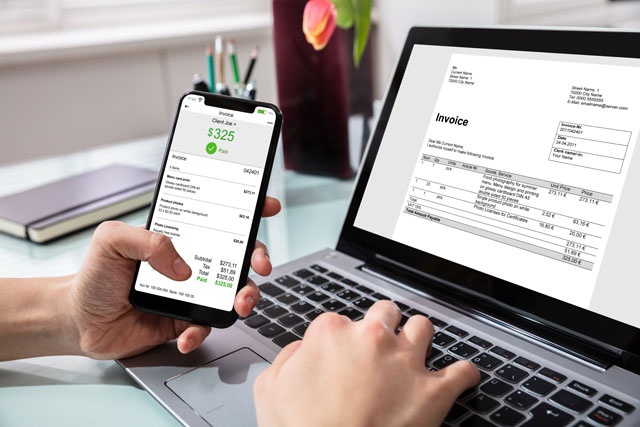

Another alternate purchasing method is the issuance of a purchasing card, or "p-card." This is a credit card that is guaranteed by the company and issued based upon the company's credit history. Purchasing cards are an invaluable resource for organizations because they allow even more flexibility for off-shift supervisors to get what they need to keep the business running.

Purchasing cards must be closely monitored for abuse. Furthermore, purchasing cards should only be issued when there is a justifiable business need. One should also consider the implementation of a tiered system of controls, such as credit limits, spot auditing, and online fraud detection provided by the card issuer.

The last alternate purchasing method we will explore is the corporate card, or corporate expense account. These are typically credit cards issued by the company; however, in most cases, they are issued based on the individual's credit. Expense accounts are the quickest and easiest opportunities for fraud, and while they offer the most flexibility, they offer very little control -- except when expense reports that justify the expenses are completed, which could be as much as 30 to 60 days after the expense was incurred. This creates an unfortunate opportunity for loss for the organization, because an employee who might be leaving the company might abuse the system prior to departure. Thankfully, if the card was issued against the employee's own social security number, there are a number of legal remedies that can be used to collect on the debt.

Control systems in any process are important, and with alternate purchasing methods, they are especially important due to their potential for abuse. Steps must be taken to reduce the risk to the organization and the supply chain management team, along with senior leadership, should implement policies, procedures, and controls that will reduce the propensity for fraud, waste, and abuse.

While supply chain management is not typically responsible for the approval of p-cards and expense accounts, supply chain management does have a duty to monitor and control the usage of these alternate payment methods.

Case Study 5:

Jim has been given a p-card because he is the second shift supervisor, and there is no purchasing staff on second shift. Jim is reluctant to use the p-card, however, on one particular evening his crew ran out of personal protective equipment; so Jim ran to Walmart to buy gloves and goggles. When he arrived back to the job, Jim issued the equipment to his staff and went on about his shift. Weeks go by and Jim is finally confronted by the production manager regarding the expense. Jim has unfortunately lost the receipt and cannot justify the expense other than via statements from his staff and himself.

Case Study Debrief:

While Jim had the best of intentions, it is essential that everything be documented. Jim was left with no real procedures or policies to follow, and that is not Jim's fault. It is the responsibility of the supply chain management function, along with senior leadership, to establish and enforce policies and procedures related to purchasing practices.

There are myriad reasons to control alternative payment methods, and there are no reasons not to. The key is implementing sustainable, reasonably flexible systems and processes that enable the organization to get the job done, while at the same time mitigating the risk of fraud, waste, and abuse.

Some of the most common control measures are listed in the following table.

|

One over-approval on spending above threshold |

Spending limits based upon position |

|

Dual signature requirement |

Authorized personnel only |

|

Regular supporting reports submitted to supply chain management by staff |

Limited to a small number of people and vendors |

|

Vendor submits reports to supply chain management |

Regularly audited |

|

On-call or online supply chain management |

Online fraud monitoring by issuer (P-Cards/Expense Accounts) |

One relative newcomer to the control system field of play for alternative payment systems is on-call, or online, supply chain management. This system, in some cases, creates a centralized purchasing function that is available 24/7, or creates an on-call system where purchases are approved by an on-call supply chain management staff member.

While this system might be particularly effective as a control, it does, in some ways, inhibit flexibility. In some cases it might be quicker for the on-shift supervisor like Jim, who has p-card authority, to just get what he needs to keep the facility operating. But what do we lose with that flexibility? The ability to source from multiple vendors, negotiate price, and negotiate terms and conditions.